의료법인 유투의료재단 신축공사

-

Location

열분해

-

Client

의료법인 유투의료재단

-

용도

1종 근린생활시설1종

-

규모

지하3층~지상7층 / 7,917.81㎡

-

공사기간

2025.02 ~ 2026.12

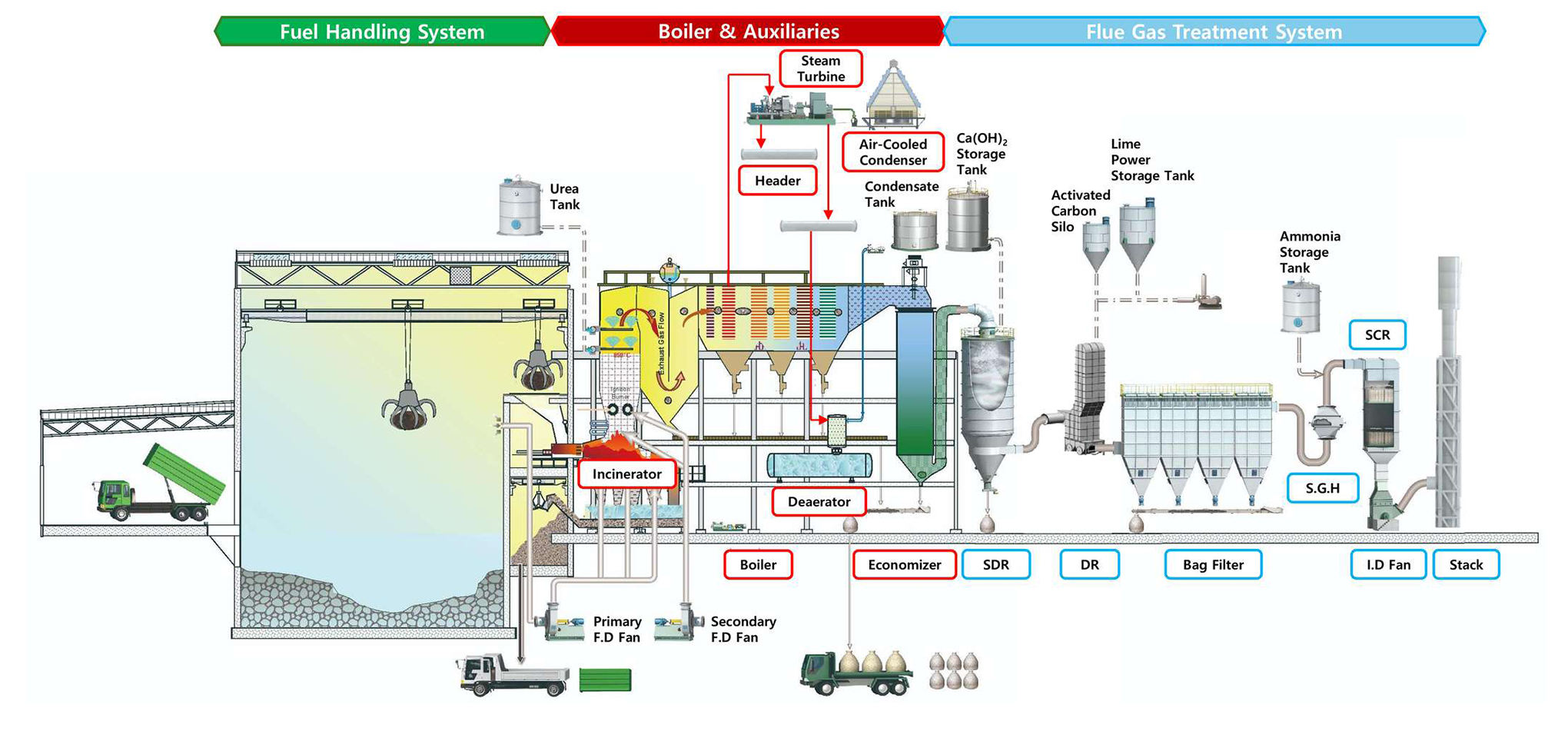

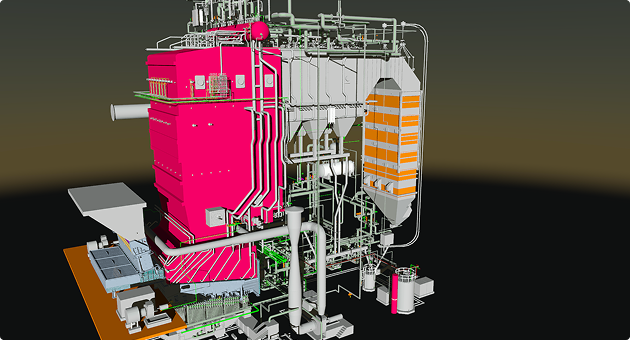

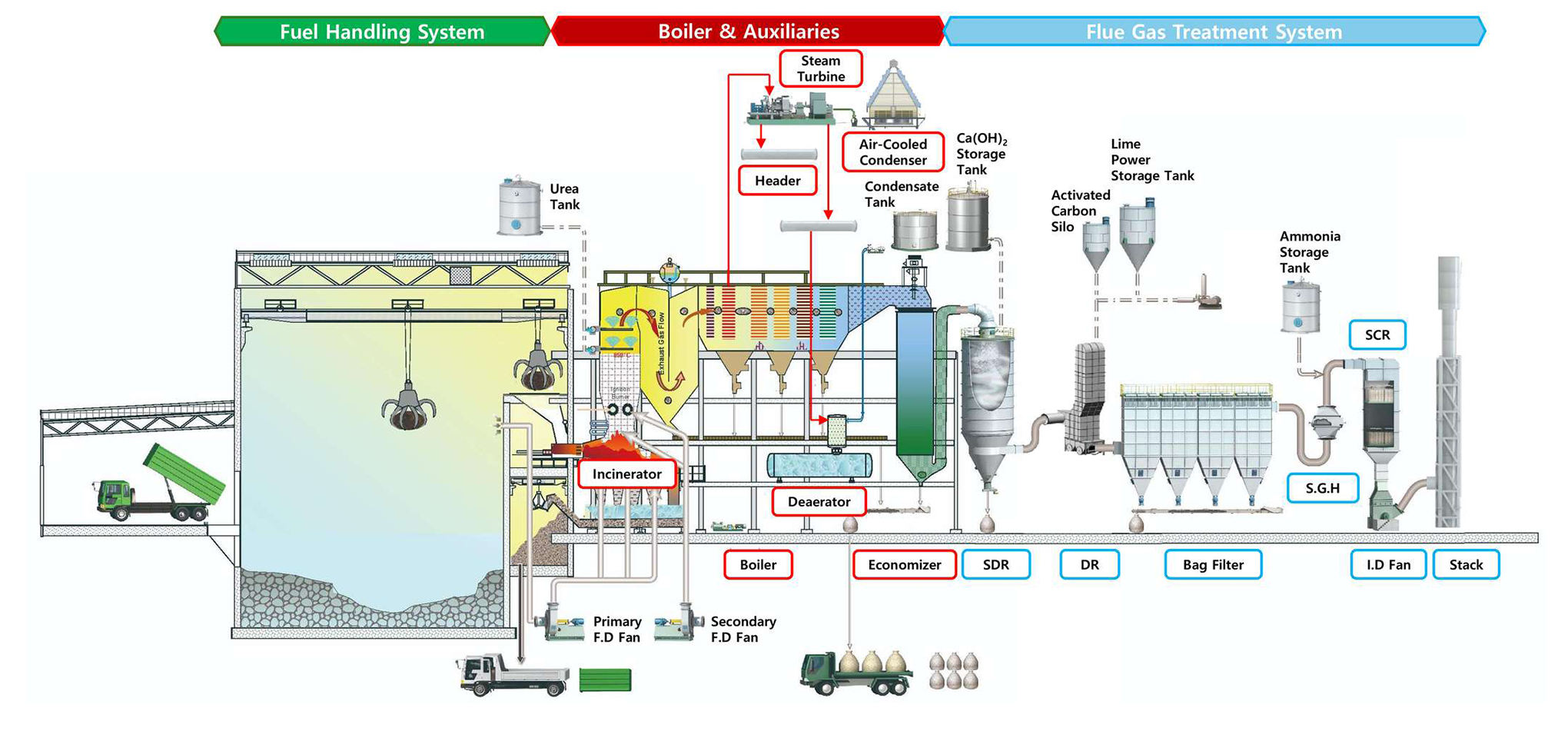

In response to the government’s decarbonization policy and coal-fired power reduction trend, we deliver integrated solutions based on waste and biomass energy conversion technologies.

Our systems combine high-efficiency combustion for municipal and industrial waste, solid refuse fuel (SRF, BIO-SRF), waste heat recovery boilers, and air pollution control systems (de-dusting, desulfurization, dust collection) to maximize facility efficiency and regulatory compliance. Through a Total Engineering Solution that covers design, manufacturing, construction, operation, and maintenance, we achieve both eco-friendliness and energy self-sufficiency.

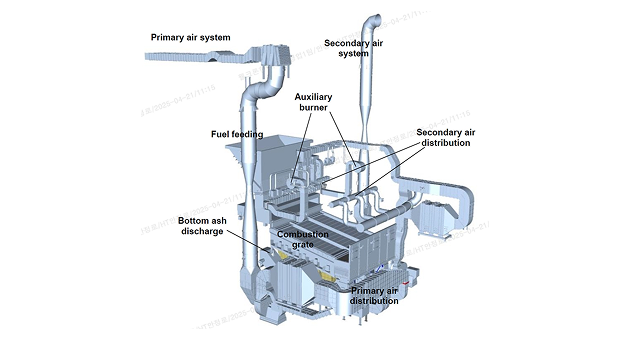

Water Cooled Grate Firing System

Capable of combusting high-calorific fuels (3,500 ~ 7,000 kcal/kg)

High-temperature combustion reduces harmful emissions

Low excess air ratio reduces flue gas volume and increases thermal efficiency

Applicable Fuels

Solid Refuse Fuel (SRF, BIO-SRF)

Industrial Solid Waste

Municipal Solid Waste

Biomass

Horizontal Tail End Boiler

Annual operation: 8,000+ hours

Easy in-furnace contamination removal

Thermal efficiency over 80%

Organic Sludge Drying Process Flow Using Steam

Hanwha - Mokpo Municipal Waste-to-Energy Plant BTO

GS E&C – Seongnam Municipal Waste to Energy Plant BTO

GS E&C – Seongseo Municipal Waste-to-Energy Plant

CEK Jeonju Unit 2 (SRF) Plant Upgrade

Rewell Energy SRF CHP Plant Construction

CEK Yeosu Industrial Waste Incineration Plant

Swipe left or right to view the content.

Swipe left or right to view the content.| Project Name | Scope of Work | Fuel | Type | Steam Condition | Completion Year |

|---|---|---|---|---|---|

| Hanwha - Mokpo Municipal Waste-to-Energy Plant BTO | Incinerator, Waste Heat Boiler |

Municipal Waste 220 ton/day |

Air Cooled Stoker | 44 ton/hr, 35 kg/㎠, 350℃ | Under Construction |

| GS E&C – Seongnam Municipal Waste to Energy Plant BTO | Waste Heat Boiler |

Municipal Waste 250 ton/day × 2 sets |

Air & Water Cooled Stoker | 51.2ton/hr, 40bar, 400℃, 2set | Under Construction |

| GS E&C – Seongseo Municipal Waste-to-Energy Plant | Incinerator |

Municipal Waste 360 ton/day |

Air & Water Cooled Stoker | 75 ton/hr, 30 bar, 300℃ | Under Construction |

| CEK Jeonju Unit 2 (SRF) Plant Upgrade | EPC |

SRF 140 ton/day |

Air & Water Cooled Stoker | 28.4ton/hr, 20bar, 212.4℃ | 2025 |

| Rewell Energy SRF CHP Plant Construction | EPC |

SRF 114 ton/day |

Air Cooled Stoker | 30.3ton/hr, 25bar, 223.9℃ | 2025 |

| CEK Yeosu Industrial Waste Incineration Plant | Incinerator, Waste Heat Boiler, Flue-Gas Treatment & Electrical System |

Industrial Waste 100 ton/day |

Air Cooled Stoker | 23 ton/hr, 53 bar, 405℃ | 2024 |

| Shindahan Refinery Industrial Waste Incinerator Replacement | EPC |

Industrial Waste 62.4 ton/da |

Air Cooled Stoker | 17.4 ton/hr, 20 bar, 214℃ | 2023 |

| KED Incineration Plant Construction | EPC |

Industrial Waste 36 ton/day |

Rotary Kiln & Air Cooled Stoker | 14 ton/hr, 20 bar, 214℃ | 2022 |

| Seohae Green Energy Heat Supply Plant | Incinerator, Waste Heat Boiler |

Bio-SRF 650 ton/day |

Water Cooled Stoker | 120ton/hr, 50bar, 400℃ | 2020 |

| Ewell Bio-SRF New Line Installation & Plant Upgrade | EPC |

Bio-SRF 110 ton/day |

Air Cooled Stoker | 17.5 ton/hr, 30 bar, 385℃ | 2015 |